Jinyu Magnet

Bonded NdFeB Magnet

Bonded neodymium iron boron is a synthetic magnet made by mixing rapidly quenched NdFeB magnetic powder and a binder through "compression molding" or "injection molding". Its main component is Nd2Fe14B, which has the characteristics of high remanence, high coercivity, and high magnetic energy product, and is suitable for various complex shaped magnetic components.

The advantages of bonding neodymium iron boron include high dimensional accuracy, flexible shape, absence of medium and heavy rare earths, low unit cost, and low losses during processing.

The application fields of bonded neodymium iron boron are very wide, mainly used in office automation equipment, electrical equipment, audio-visual equipment, instruments and meters, small motors and measuring machinery, mobile phones and other fields. Due to its high dimensional accuracy, large degree of shape freedom, good mechanical strength, and light specific gravity, bonded neodymium iron boron has been widely used in modern electronic products.

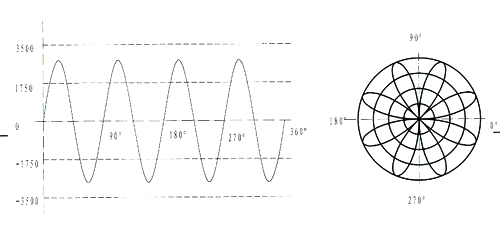

Bonded neodymium iron boron magnets have extremely high dimensional accuracy, good magnetic uniformity and consistency, and can be made into complex shapes that are difficult to achieve on sintered neodymium iron boron magnets. They are also easy to integrate with other metal or plastic components for molding. Bonded neodymium iron boron magnets have the characteristics of diverse magnetization methods, low eddy current losses, and strong corrosion resistance.

Advantage:

• Easy to integrate and form • Various magnetization methods • Good magnetic uniformity • Strong corrosion resistanceProducts show

Performance Table

Model |

HB-6 |

HB-8 |

HB-10 |

HB-12 |

HB-8H |

|---|---|---|---|---|---|

Br (T) |

0.52-060 |

0.60-0.65 |

0.65-0.70 |

0.70-0.76 |

0.55-0.62 |

KA/mbHc |

304-360 |

360-440 |

360-960 |

424-480 |

400-480 |

KA/miHc |

640-800 |

640-960 |

640-960 |

424-880 |

960-1280 |

KJ/m3(BH) |

40-56 |

56-72 |

72-80 |

80-96 |

48-72 |

D ( g/cm3) |

5.3-5.8 |

5.6-6.0 |

5.8-6.1 |

6.0-6.2 |

5.6-6.0 |

ur |

1.15 |

1.15 |

1.22 |

1.22 |

1.15 |

a Br( %/°C) |

-0.13 |

-0.13 |

-0.07∽0.1.5 |

-0.13 |

-0.07∽-0.13 |

Tw( °C) |

120 |

120 |

120 |

130 |

130 |